When I first learned bookbinding, we did not use sewing frames. It wasn’t until I started learning more advanced techniques that I first used a sewing frame. At the time, it seemed unnecessary and a bit of a nuisance. The struts just got in the way, and I didn’t think it made sewing any easier. However, now that I’ve made lots and lots of books, my views have changed. Firstly, pre-punching signatures takes A LOT of time, so I abandoned my punch cradle. Now I stack the signatures together and use a saw to cut the holes all at once. This does not work for my albums, however. Because of the guards, I can’t stack them easily, and clamping them together to saw gets them all out of alignment again. It’s a headache. Since I’m only going through two layers of paper for these albums, I don’t really need pre-made holes to make pulling the needle and thread through easier, just to keep everything in alignment.

When I first learned bookbinding, we did not use sewing frames. It wasn’t until I started learning more advanced techniques that I first used a sewing frame. At the time, it seemed unnecessary and a bit of a nuisance. The struts just got in the way, and I didn’t think it made sewing any easier. However, now that I’ve made lots and lots of books, my views have changed. Firstly, pre-punching signatures takes A LOT of time, so I abandoned my punch cradle. Now I stack the signatures together and use a saw to cut the holes all at once. This does not work for my albums, however. Because of the guards, I can’t stack them easily, and clamping them together to saw gets them all out of alignment again. It’s a headache. Since I’m only going through two layers of paper for these albums, I don’t really need pre-made holes to make pulling the needle and thread through easier, just to keep everything in alignment.

So my thoughts returned to the sewing frame. This could keep my linen tapes straight. Now if only those darn struts would get out of the way.

Behold, the marvel of engineering: the cantilever!

This sewing frame took me a single naptime to make. So easy. And you want to know what’s even better? It took me the same amount of time to sew the book block as it usually does, but without all the time pre-punching the pages. Such a time saver, and as we discussed in my previous post, time is money.

To make your own, you will need:

- Two 3/4″ hardwood squares (next to the dowels at the hardware store)

- One 1/2″ dowel

- A pack of four 3/4″ galvanized steel L-brackets with accompanying screws

- Four small rubber washers (plumbing section)

- Four wood screws

- A piece of wood for the base of the frame (mine is a scrap left over from building shelves, 15 1/4″ x 11 1/4″, which turned out to be the perfect size)

- A drill

I’ll give you my measurements for everything if you want to replicate it exactly, but it’s not hard to figure out if you want to make one smaller or bigger.

Cut four pieces of the 3/4″ hardwood square at 11 1/4″, and one piece at 13 3/4″. Cut the 1/2″ dowel at 15″. Every time I tell you to screw something, read, “Pre-drill, then screw.” Don’t skip pre-drilling. You think it’s faster just to screw until you split the wood and have to start over, only you don’t have any more wood so you have to go back to the hardware store, which means you just wasted naptime. Don’t skip it. Screw the struts to the cantilevered portion of the frame with the L-brackets, then screw those to the base. Screw the longer piece between the cantilevers with wood screws.

Screw the dowel under the front of the base using the rubber washers as spacers. And you’re done! Easy peasy lemon squeezy.

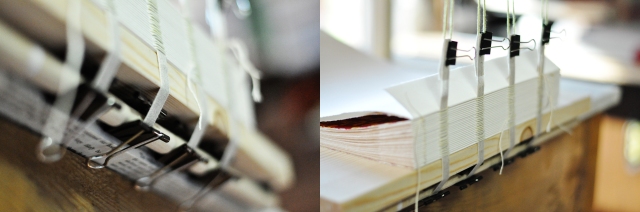

I used regular size binder clips to secure the tapes to the dowel and mini binder clips to keep the tapes looped over the strings hanging down. I have plans for adding a fence to jog the signatures against to keep everything square, but for now, I’m just using my boxmaking weight. Don’t know what that is? Guess you’ll have to stay tuned to find out 😉

I have plans for adding a fence to jog the signatures against to keep everything square, but for now, I’m just using my boxmaking weight. Don’t know what that is? Guess you’ll have to stay tuned to find out 😉

Simple, practical and affordable – that’s how I like my moddings!

Clever thinking overall, I especially like the handiness of the dowel detail.

Well, I didn’t really want to bust out my jig saw to cut a slot, and I really like how this brings the sewing to the edge of the platform, and the dowel butts up against the edge of my table so the frame doesn’t move while I’m sewing. Laziness is the mother of all invention 😉

sawing the station openings rather than punching….i love it! will most certainly be doing this on my next project. i’m thinking an 18 or 24 tooth hacksaw blade should do well and not cause too much damage.